Research never tasted so good

- Emily Allen

- Aug 9, 2023

- 2 min read

The Hatchery Food Truck is Serving Some Extra Special Oysters This Weekend!

This week something deliciously nerdy in the aquaculture world is about to happen at Oyster Seed Holdings and we’re excited to share this RaD project with you! The Hatchery Food Truck this week is serving fresh oysters grown out of a Recirculating Aquaculture System (RAS) - a technology still developing in the oyster industry.

It’s safe to say that here at OSH we have our hands in a lot of different ventures pertaining to aquaculture. While our facility is most commonly known for our work in growing and selling oyster seed and larvae for commercial oyster growers, we spend a lot of time and energy investing into the research and development of oyster aquaculture too.

R&D is an important part of what we do, and we are currently participating in a handful of projects spanning all along the East Coast. The goal of many of these projects is to advance the industry’s knowledge and practices to be better prepared to sustain operations through environmental stressors, pathogens, or water quality issues that can obstruct mollusk survival along the way.

VIMS C-SALT team grew & analyzed the RAS oysters

Cradle-to-Grave - Larvae to Plates

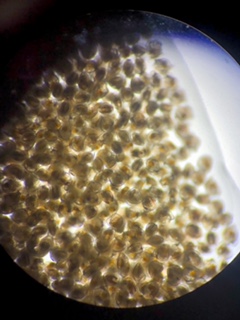

In 2021, OSH received a Fisheries Resource grant to develop a commercial scale Recirculating Aquaculture System (RAS) for larval culture. This design was implemented and tested throughout the season and in 2022, OSH partnered in a NOAA Saltonstall-Kennedy (SK) grant secured by the Seafood AREC/Dept. Food Science at Virginia Tech to further evaluate the use of RAS technology for commercial production of larvae.

There are a lot of instances where the water quality in the water adjacent to the hatchery can become incompatible with good larvae growth, which can result in high mortality. RAS is essentially an aquariam-like environment where water recirculates in a controlled environment. What this could mean for hatcheries in the long run is that they have an alternative water source during periods of poor water conditions. (Read about our water chemistry project here.)

R&D Manager at OSH, Sam Glover, played a big role in the early monitoring of these larvae in the RAS systems, and when asked about bringing these oysters back full circle to OSH’s food truck menu this weekend, she responded:

“It’s like eating my children!”

RAS-Reared Oysters Served at The Hatchery!

For a year now, to support our FRG efforts, Bill Walton’s Commercial Shellfish Aquaculture Lab & Team (C-SALT) at VIMS, led by Jordan Lynch, has been growing up to market size the larvae grown in OSH’s RAS system and has analyzed them alongside seed from the same cohort that was grown using standard operating procedures in the hatchery.

The data suggests that there was no difference in survival or growth between the two treatments, which means that RAS systems (once we get them working a bit better) are a viable alternative for larvae production!

All that work, so, let’s eat ‘em!

Thanks to Matheson Oyster Company for helping process and deliver these VIMS-reared and researched oysters for us to serve fresh, fried and raw this weekend. Come be one of the first to try these RAS-reared oysters in our area, and let us know what you think. Check us out at www.thehatcheryculture.com